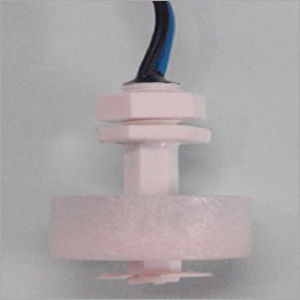

Magnetic Float Switches

450 INR/Unit

Product Details:

- Temperature Range 0C to 80C

- Protection Level IP65

- Automation Grade Automatic

- Max. Current 0.5A

- Finish Type Polished / Matt

- Mechanical Life >100,000 operations

- Rated Voltage 220V AC

- Click to view more

X

Magnetic Float Switches Price And Quantity

- 450 INR/Unit

- 10 Unit

- 30cm (customizable)

- Liquid Level Sensing in Water, Oil, Chemicals

- 10W (max)

- PVC / Teflon

- 25mm (standard)

- IP65/IP67 (varies by model)

- SPST (Single Pole Single Throw)

- Atmospheric

- 0.7g/cm

Magnetic Float Switches Product Specifications

- Polished / Matt

- 0.5A

- 0C to 80C

- 100 M at 500V DC

- Single

- Metallic / White

- Magnetic Float Switch

- <10ms

- Automatic

- 150 m

- 0C to 80C

- NO / NC (Normally Open / Normally Closed)

- 0.5A

- IP65

- Stainless Steel / Polypropylene (PP)

- 220V AC

- Customizable (Standard: 80mm length)

- 10-40mm

- Vertical / Horizontal

- Approx. 35g

- 220V AC

- >100,000 operations

- Single Pole

- 30cm (customizable)

- Liquid Level Sensing in Water, Oil, Chemicals

- 10W (max)

- PVC / Teflon

- 25mm (standard)

- IP65/IP67 (varies by model)

- SPST (Single Pole Single Throw)

- Atmospheric

- 0.7g/cm

Magnetic Float Switches Trade Information

- 100 Unit Per Week

- 1 Week

Product Description

Miniature Level Switch is offered with a compact construction and is highly suitable for vertical mounting. This is included with a Reed Switch contained inside the permanent magnet and guide tube. This is apt for the detection of low, high and both high & low level in tanks. Miniature Level Switch has long operating life and provides efficient operation in the demanding operating conditions. It has exclusive design and ensures high accuracy fluid level detection of several acids as well as chemicals.

Specification

- Material : Stainless Steel

- Type: Level Switch

- Application : Miniature Leveling

- frequency : 50 Hz, 60Hz

- Power: 0-5 Amp

Versatile Application in Liquid Level Sensing

Magnetic Float Switches are ideal for monitoring liquid levels in water, oil, and chemical environments. With both vertical and horizontal mounting options, these switches adapt effortlessly to various installation setups. The use of stainless steel or polypropylene materials ensures compatibility with different media densities and aggressive chemicals. Their reliable contact operation and customizable cable lengths make them suitable for countless industrial and commercial applications.

Durable Build and Reliable Operation

Built for longevity, our switches promise mechanical life exceeding 100,000 operations. Rated for operation in temperature ranges from 0C to 80C and equipped with ingress protection up to IP67, these switches deliver excellent performance in challenging environments. Low contact resistance and high insulation resistance further enhance operational safety and reliability, making them a dependable choice for liquid handling systems.

FAQs of Magnetic Float Switches:

Q: How do magnetic float switches work in liquid level sensing?

A: Magnetic float switches detect the presence or absence of liquid by using a moving float that activates a magnetic reed switch. As the liquid rises or falls, the float moves correspondingly, opening or closing the electrical contact for level monitoring or control.Q: What customization options are available for cable length and size?

A: Standard cable length is 30cm, and the default switch length is 80mm. However, both cable length and switch size can be customized to accommodate specific installation requirements, ensuring flexibility for various tank sizes and configurations.Q: When should I choose stainless steel over polypropylene float switches?

A: Select stainless steel models for high-temperature, aggressive, or chemically reactive liquids where greater mechanical strength and corrosion resistance are required. Polypropylene versions are ideal for water or oils and provide excellent chemical compatibility at a lower cost.Q: What is the installation process for these float switches?

A: Installation involves securing the float switch vertically or horizontally into a tank using the provided mounting options. After positioning, simply connect the lead wires (PVC or Teflon) to your control system. No complex tools or calibration are needed.Q: Where can these magnetic float switches be used effectively?

A: They are widely used in industrial tanks, water reservoirs, oil containers, and chemical storage systems in both commercial and industrial environments. Their IP65/IP67 ratings make them suitable for both indoor and outdoor placements.Q: What are the benefits of using this magnetic float switch in automation systems?

A: These switches offer fast response time (<10ms), high mechanical durability, and simple design for reliable operation. They enhance liquid management efficiency by enabling automatic level control, minimizing manual intervention, and ensuring consistent operation.Q: What is the maximum switching power and voltage these switches can handle?

A: The maximum switching power is 10W, with a rated operational voltage up to 220V AC and a current rating of 0.5A. This ensures safe and effective performance in most standard liquid level control systems.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email