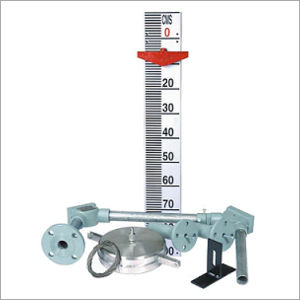

Flap Assembly for Magnetic Level Indicator

4500 INR/Piece

Product Details:

- IP Rating IP65 (when used in MLI)

- Measuring Range Custom according to Magnetic Level Indicator design

- Protection Level Corrosion-resistant construction

- Sensor Type Magnetic

- Installation Type Pre-fitted on Magnetic Level Indicator tube

- Usage & Applications Chemical, Petrochemical, Water Treatment, Power Plants, Process Industries

- Features Bicolor display, Corrosion resistance, High visibility, Maintenance free, Non-powered

- Click to view more

X

Flap Assembly for Magnetic Level Indicator Price And Quantity

- 1 , , Piece

- 4500 INR/Piece

- Customizable for aggressive media

- -40°C to +80°C (for display visibility)

- UV stabilized flaps available for outdoor installation

- Maintenance-free operation

- Typically 24-30 mm (customizable)

- Red for liquid presence, White for absence

- High-grade Polycarbonate / Aluminum / SS304 / SS316 (as per design)

- 180° flip for indication

- Over 1 million cycles

- Multi-pole permanent ceramic or rare earth magnet encapsulated

- up to 20 bar or as per Level Indicator capacity

Flap Assembly for Magnetic Level Indicator Product Specifications

- Corrosion-resistant construction

- Magnetic

- Pre-fitted on Magnetic Level Indicator tube

- Magnetic track mounting

- Used in Magnetic Level Indicators for liquid level visualisation

- Flap Assembly for Magnetic Level Indicator

- Custom according to Magnetic Level Indicator design

- Mechanical magnetic flap display, Red/White color

- up to 200C

- IP65 (when used in MLI)

- Suitable for process pressure up to 20 bar

- 5 mm

- Bicolor display, Corrosion resistance, High visibility, Maintenance free, Non-powered

- Approx. 50-150 grams per assembly

- Chemical, Petrochemical, Water Treatment, Power Plants, Process Industries

- Standard 8 mm and 10 mm (custom available)

- Visual Indication

- -40C to +200C

- Mechanical only

- As per indicator design

- Customizable for aggressive media

- -40°C to +80°C (for display visibility)

- UV stabilized flaps available for outdoor installation

- Maintenance-free operation

- Typically 24-30 mm (customizable)

- Red for liquid presence, White for absence

- High-grade Polycarbonate / Aluminum / SS304 / SS316 (as per design)

- 180° flip for indication

- Over 1 million cycles

- Multi-pole permanent ceramic or rare earth magnet encapsulated

- up to 20 bar or as per Level Indicator capacity

Flap Assembly for Magnetic Level Indicator Trade Information

- 10 , , Piece Per Day

- 1 Days

Product Description

Flap Assembly for Magnetic Level Indicator is utilized to specify the level of liquid. It has been engineered and made in accordance with the appropriate regional as well as global design standards. It has a weather proof body and stainless-steel construction. It works with high accuracy and precision. Flap Assembly for Magnetic Level Indicator can be used for the aggressive media stowed in vessels. It is fortified with a ring system of enduring magnets.

Precision and Durability in Industrial Measurement

Engineered with premium materials including Polycarbonate, Aluminum, and Stainless Steel variants (SS304/SS316), the Flap Assembly is designed to withstand aggressive media, corrosive conditions, and wide temperature ranges. UV-stabilized flaps ensure clear visibility in outdoor installations, while corrosion resistance and mechanical robustness guarantee a long, maintenance-free service life exceeding 1 million cycles.

Clear Liquid Level Indication

This mechanical flap assembly provides immediate visual feedback through a 180 bicolor flip: Red signifies liquid presence, and White indicates absence. The magnetic sensor design and customizable flap length (2430mm) ensure accurate (5mm) and highly visible level status at a glance, without requiring any power or complex connectivity.

Flexible Integration and Customization

Designed for pre-fitting onto Magnetic Level Indicator tubes and compatible with magnetic track mounting, this assembly is suitable for a range of applications. Options for material, diameter (8mm/10mm or custom), and chemical compatibility allow seamless integration across various industrial processes, from petrochemicals to water treatment plants.

FAQs of Flap Assembly for Magnetic Level Indicator:

Q: How does the Flap Assembly visually indicate liquid levels in a Magnetic Level Indicator?

A: The Flap Assembly uses a 180 rotating bicolor flap driven by a multi-pole encapsulated magnet. When liquid is present, the flap displays red; when absent, it shows white, allowing immediate and clear level visualization without electrical components.Q: What materials are available for the construction of the Flap Assembly?

A: Depending on application requirements, the assembly can be manufactured from high-grade Polycarbonate, Aluminum, SS304, or SS316. The material selection is customizable for enhanced corrosion resistance or compatibility with aggressive chemicals.Q: When should UV-stabilized flaps be chosen for a level indicator?

A: UV-stabilized flaps are recommended for installations exposed to sunlight or harsh outdoor environments, ensuring color integrity and reliable visual performance under intense UV exposure over time.Q: Where can the Flap Assembly be installed and what are its installation options?

A: The assembly is designed to be pre-fitted onto Magnetic Level Indicator tubes and supports magnetic track mounting, ensuring secure and precise placement on a variety of indicator models used in chemical, power, and water treatment industries.Q: What is the service life of a typical Flap Assembly, and is maintenance required?

A: The Flap Assembly is engineered for a service life of over 1 million cycles and is virtually maintenance-free, thanks to its durable, corrosion-resistant construction and reliable mechanical operation.Q: How is the flap length or diameter customized to fit specific applications?

A: Flap length (usually 2430mm) and diameter (standard 8mm or 10mm, with custom sizes available) can be tailored during the manufacturing process to suit specific Magnetic Level Indicator designs and required measuring ranges.Q: What are the key benefits of using this Flap Assembly in industrial applications?

A: Key benefits include high visibility, reliable color-coded indication, corrosion resistance, UV stability, maintenance-free operation, mechanical only (no power required) visual output, and customizable construction to match process and media needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email